INTEGRATED PLANT

TECHNOLOGIES

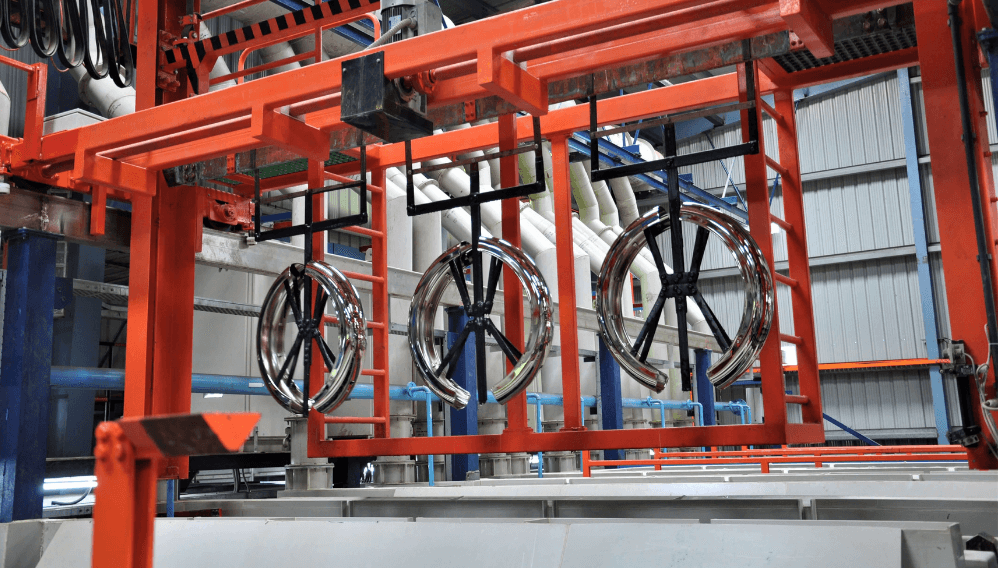

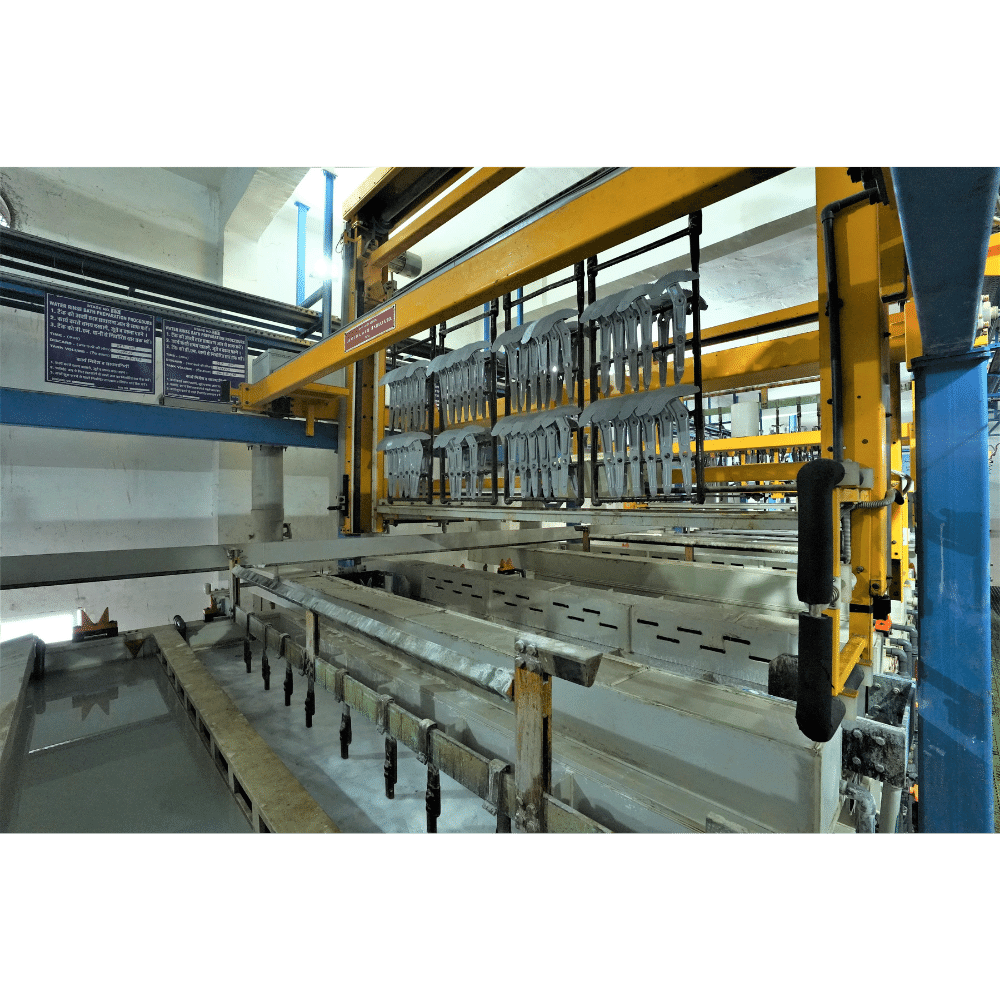

RACK PLATING PLANT

REQUEST A QUOTE

Contact us for free Consultation

PLANT TECHNOLOGIES

RACK TYPE PLANT

Growel’s Rack Plating Plants are designed for

high-quality, uniform electroplating of components

requiring precise handling and superior surface finishing. Components are securely mounted

on racks and individually processed, enabling accurate control of current

distribution and coating thickness.

Each plant integrates advanced plating technology and robust engineering for durability, corrosion resistance, and

aesthetic enhancement. The system supports multiple plating processes — nickel,

copper, chrome, zinc, and others — ensuring reliability,

precision, and consistent performance. Built to international standards, Growel’s rack plants combine mechanical strength with

modern automation and process flexibility.

In this system, parts are fixed on custom racks, jigs, or

hooks, which are immersed into process tanks of varying sizes

based on component geometry and production volume. The plants are fully

customizable to meet specific client and process

requirements.

Talk to us

+91-20-35553555

APPLICATIONS

INDUSTRY AND USAGES

high-quality, uniform, and durable finishes across a variety of components and industries:

Automotive

Bumpers, fasteners,

brackets, trims, and other parts requiring corrosion resistance, durability,

and decorative finishes.

Aerospace

Structural

components, fittings, and precision parts that require lightweight,

corrosion-resistant, and high-strength coatings

Defense

Hardware and

components that demand strict adherence to quality, corrosion protection,

and reliability under extreme conditions.

ELECTRICAL

Connectors,

terminals, switches, and small components needing uniform conductivity and

precise coating thickness.

HARDWARE

Locks, hinges,

handles, brackets, and other hardware components requiring durable and

decorative finishes that enhance both performance and appearance.

General

Manufacturing

Decorative and

functional plating for consumer goods, industrial equipment, and hardware

components, ensuring long-lasting finishes and enhanced aesthetics.

FEATURES AND SPECIFICATION

TYPES OF RACK PLANTS

Standard Tree or Vertical

Racks

Finger Racks / Contact

Racks

Conforming Anode Racks

Custom or

Product-Specific Racks

Rotary / Spinning Racks

Vibratory Racks

Rack Plating Plant

Flexible hybrid system handling

both small & large components in one plan

Ability to handle various

finishes with a range of components in the same plant

Enhanced Growel Automation

Features

Contemporary Material Handling

System

Integrated PLC controlled Fume

Extraction System

Comprehensive features for Man

and Machine safety

Extremely Maintenance-Friendly

Design

Designed to optimize Water

Consumption

Plants available with

Automatic, Semi-Automatic and Manual options

robust, corrosion-resistant

racks and jigs

Advanced filtration and

solution agitation systems

AUTOMATION & SOFTWARES

ELECTROPLATING AUTOMATION SOFTWARE

Growel Engineering stands apart in

delivering services due to several key advantages:

Automated Cycle Control

Fully automated plating

sequences ensure uniform coating thickness with minimal operator intervention.

Real-Time Monitoring

Continuous tracking of

voltage, current, bath temperature, and process timing maintains consistent quality.

Intelligent Fault Detection

Smart diagnostics with

SMS/email alerts enable quick response, reducing downtime and improving safety.

Data Logging &

Traceability

Captures all process

parameters, events, and alarms for quality audits and productivity analysis.

Optimized Resource

Management

Automated control of

rectifiers, heaters, and dosing systems reduces energy and chemical consumption.

Multi-Process

Compatibility:

Supports electroplating,

anodizing, pickling, phosphating, and other treatments within the same system.

Talk to us

+91-20-35535555

GROWEL OFFERINGS

ADDITIONAL FEATURES & EQUIPMENTS

Growel’s Rack Plating Plants are

designed with advanced features to ensure efficiency, safety, and consistent plating quality:

Fume & Exhaust

System

Removes toxic

fumes, gases, and vapors from the working area, ensuring a safe and

pollution-free environment.

Dosing system

Automatic chemical

dosing for precise control and consistent bath performance, reducing manual

errors and chemical wastage.

Metal Recovery

System

Efficient metal

reclamation reduces raw material consumption and supports sustainable

operations

Effluent Treatment

Plant

Integrated

wastewater treatment ensures regulatory compliance and environmentally

friendly operation.

SUCCESS STORIES

OUR CASE STUDIES

GALLERY

Showcasing our Successful Projects and

Installations

Demo Videos

SEE OUR MODULES IN ACTION

THINGS YOU MIGHT ASK

FAQ’S

What is a rack

plating plant, and what are its applications?

A rack plating

plant is designed for electroplating large or complex parts that require

individual handling, commonly used in the automotive and aerospace

industries.

How does Growel’s

rack plating system ensure uniform coating?

Our system

employs precise current control and optimized rack designs to achieve

consistent and uniform plating across all parts.

Can the rack

plating plant be customized for specific part geometries?

Yes, we offer

customized rack designs and configurations to accommodate various part

sizes and shapes.

What materials

can be plated using the rack plating plant?

Broadly, our

system supports plating on materials like steel, aluminum, brass, zinc,

etc. using various plating solutions.

Does Growel

provide automation options for the rack plating plant?

Yes, we offer

semi-automatic and fully automatic systems to enhance efficiency and

reduce manual intervention.